Ions as a chance for monuments containing cellulose

30-03-2023

Valuable items made of wood-based materials, such as old books or sculptures, can be more effectively protected against moisture or rotting. Such an optimistic conclusion can be drawn from research on the implantation of cellulose with metal ions and noble gases, carried out at the National Center for Nuclear Research and the Warsaw University of Life Sciences.

Since the dawn of our species, wood has been one of the most important construction materials. Widely available in ecosystems inhabited by humans, due to its unique mechanical properties, it has found a number of applications, including inventions of key civilization importance, such as ships or paper. Unfortunately, despite many advantages, wood has a significant disadvantage: limited durability. Cellulose, which is its main component, as a hygroscopic material has the ability to bind water, which promotes the development of fungi, including those that decompose cellulose. In the interests of increasing the durability of valuable wood products and wood-based materials, scientists at the National Center for Nuclear Research (NCBJ) in Swierk and the Warsaw University of Life Sciences (SGGW) have initiated research into the possibility of increasing the durability of cellulose using a process known as ion implantation.

„The implantation procedure consists in modifying the surface layer of the material with a beam of ions of specific elements. The final properties of the transformed surface are determined by a number of factors, including skilful selection of the type of ions, as well as the time and method of exposing the object to the beam”, explains Marek Barlak, PhD from the Department of Plasma and Ion Technologies of the National Center for Nuclear Research. Scientists from Świerk and Warsaw set two goals: to verify whether ion implantation can reduce the tendency of cellulose-based materials to absorb water, and to determine whether it can protect the modified surface against the development of harmful fungi. Bacterial cellulose produced at the Institute of Wood Sciences and Furniture of the Warsaw University of Life Sciences was used for the research. The samples resembled scraps of paper with an extensive texture. Implantation with noble gas and metal ions was carried out in an implanter working at the National Center for Nuclear Research. The process was carried out in a vacuum chamber, where the samples were exposed to an ion beam with a diameter of about 6 cm and kinetic energy selected in such a way that the accelerated particles could penetrate the surface layer of the material to a precisely selected depth.

In the case of studies on the hydrophobicity of cellulose, the role of projectiles was played by ions of noble gases, helium and argon, implanted separately in two doses. In all cases, the modified fragments of the sample showed significantly lower wettability than the unmodified surface areas. Analyzes revealed that argon ions were located relatively shallow, in a layer lying about 70 nanometers below the surface, while helium penetrated to a depth of up to 600 nm. The observed differences will allow in the future to better match the type of implantation to the properties and condition of the protected object.

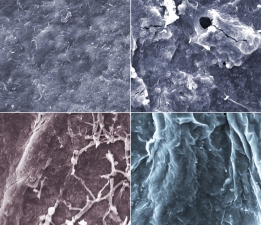

The heroes of the second stage of research were metal ions: copper, zinc and silver. These elements were selected due to their presence in compounds used to protect wood against fungi. As before, implantation with each metal was carried out in two different doses. The modified samples were then transported to the Warsaw University of Life Sciences, where they were placed in the presence of Trichoderma viride and Chaetomium globosum. The test results turned out to be promising only for samples modified with a higher dose of silver ions.

„Our biological tests have shown that silver ions implanted on the surface of cellulose have a biocidal effect on one of the most important fungi responsible for the decomposition of cellulose, namely Trichoderma viride. In nature, these microscopic fungi can be found on the surface of decomposed wood, they are also commonly found in the soil,” says Izabela Betlej, PhD (SGGW), the first author of the article published in the journal „Coatings”. It is worth emphasizing that both when reducing wettability and increasing fungal resistance, the course of implantation lasting several minutes turned out to be harmless to the samples: their surface temperature never exceeded 50 degrees Celsius, a safe value even for organic materials.

Due to the promising results, the initiated research direction will be continued.

SCIENCE PUBLICATIONS:

„Effect of Cu, Zn and Ag Ion Implantation on the Surface Modification of Bacterial Cellulose Films” I. Betlej, M. Barlak, K. Krajewski, B. Andres, Z. Werner, A. Jankowska, S. Zakaria, P. Boruszewski, Coatings 13 (2), 254, 2023DOI: https: 2023//doi. org/10.3390/coatings13020254

ILLUSTRATIONS:

photo. 1. Marek Barlak, PhD at the vacuum chamber of the ion implanter at the National Center for Nuclear Research in Świerk. (Source: NCBJ)

photo. 2. Microscopic photos of cellulose samples, magnification approx. 2000x, artificial colors. Top row: stock sample and zinc-implanted sample treated with fungus (visible numerous black cracks indicating cellulose degradation). Bottom row, both samples treated with fungi: after copper implantation (single cracks; fungal threads visible in the right part of the frame) and after silver implantation (no cracks). (Source: NCBJ/SGGW)