Simulations of components subjected to mechanical and thermal loads

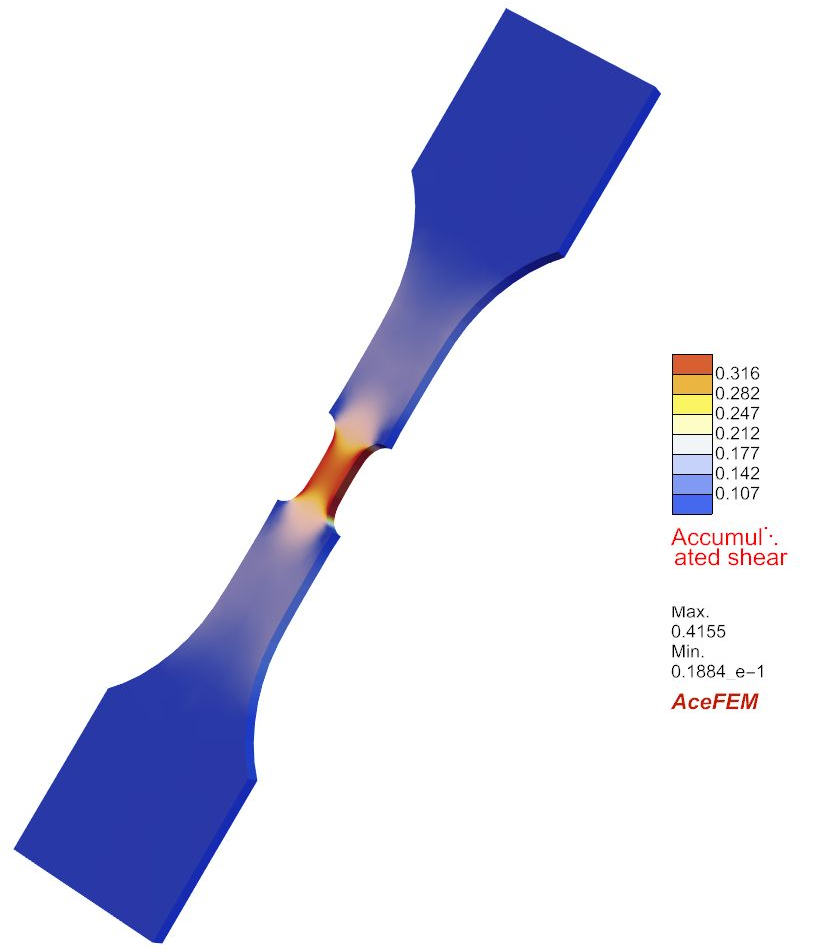

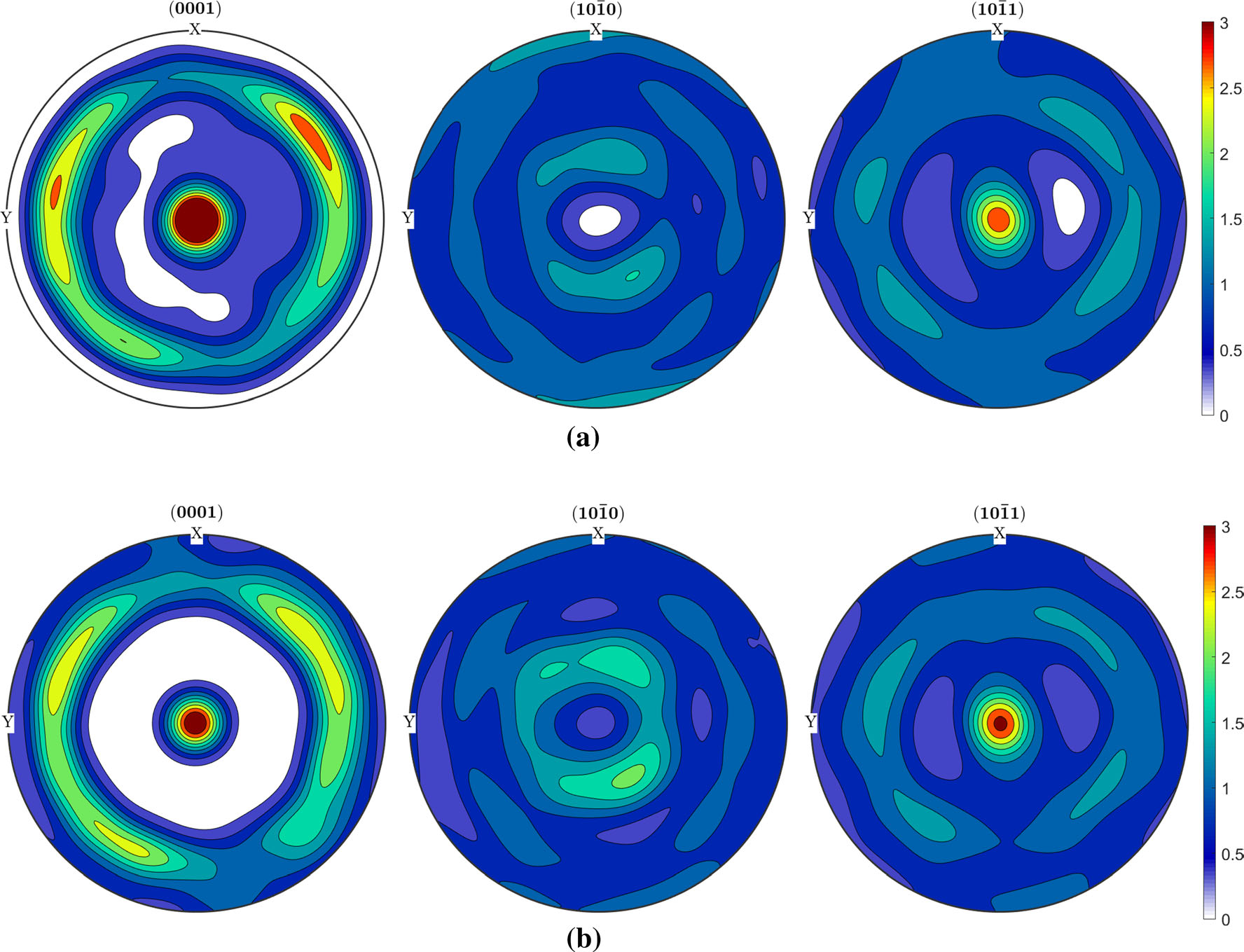

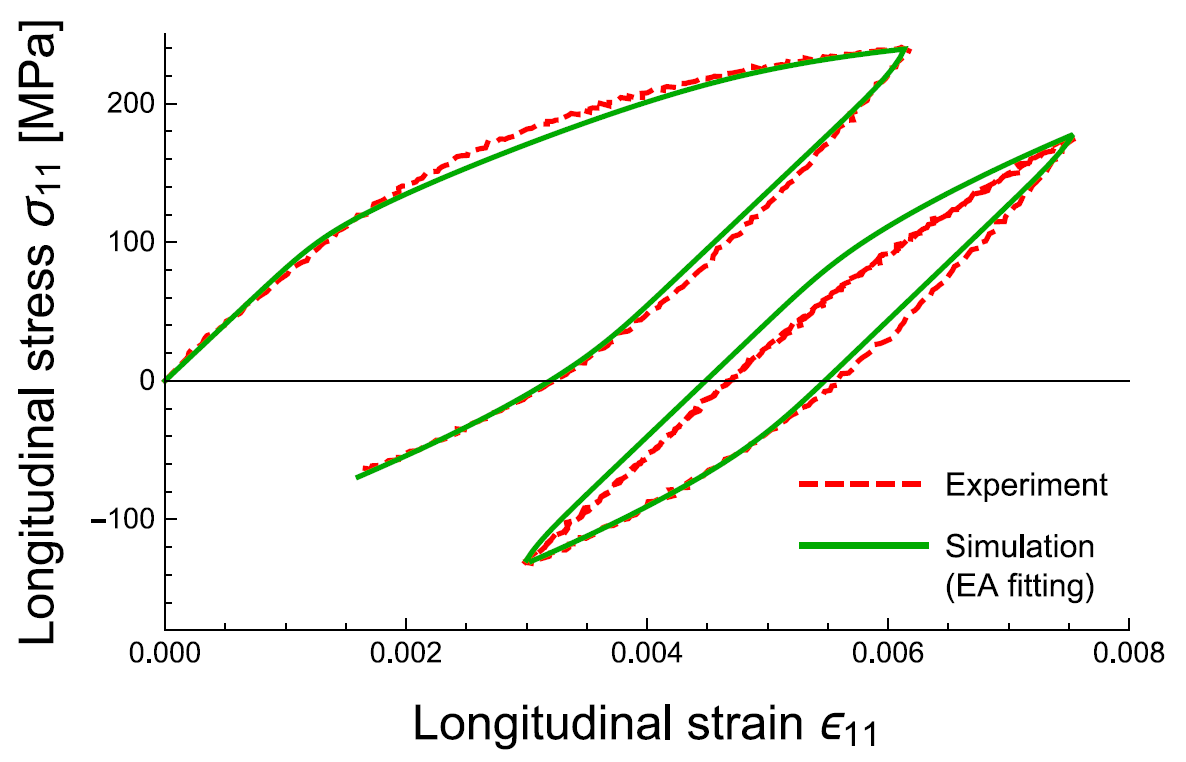

By simulating the component, taking into account its shape, material and the mechanical and thermal loads present, it is possible to determine the state of the material. It is possible to determine the state of stress, plasticisation zone, temperature distribution, etc. The simulation result gives an indication of the areas most susceptible to damage or wear. It can also help to select a material suitable for the manufacture of a part.