VT - visual methods

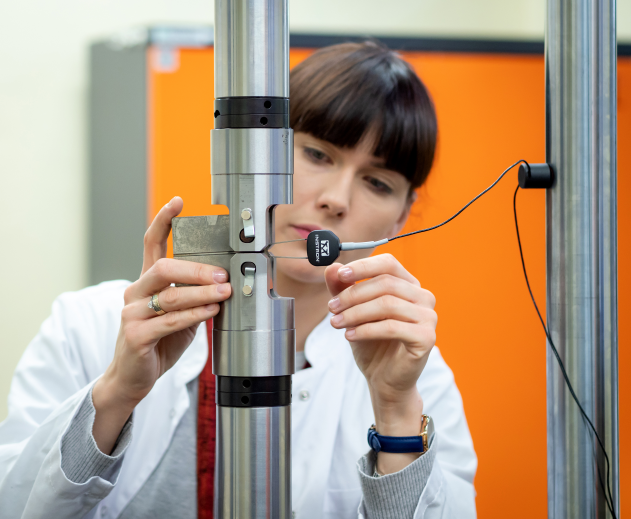

Visual testing is an NDT method that involves an examination with the unaided eye to detect, locate and evaluate a discontinuity or defect present on the surface of the material being tested. It is the oldest NDT method and considered one of the most important. The method is applicable at all stages of construction and/or production of a component or process installation.

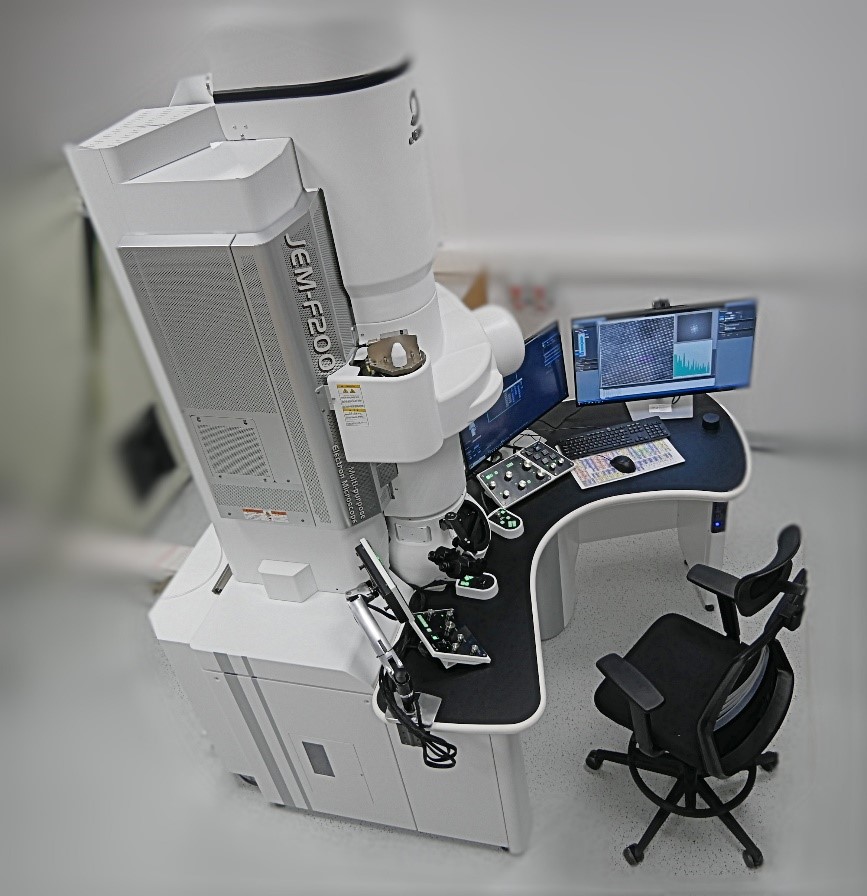

Visual inspection is usually performed using unaided eyes. The effectiveness of the method can be improved by using special tools such as mirrors, magnifying glasses (magnifiers, telescopes) and boroscopes, fiberscopes, videoendoscopes.

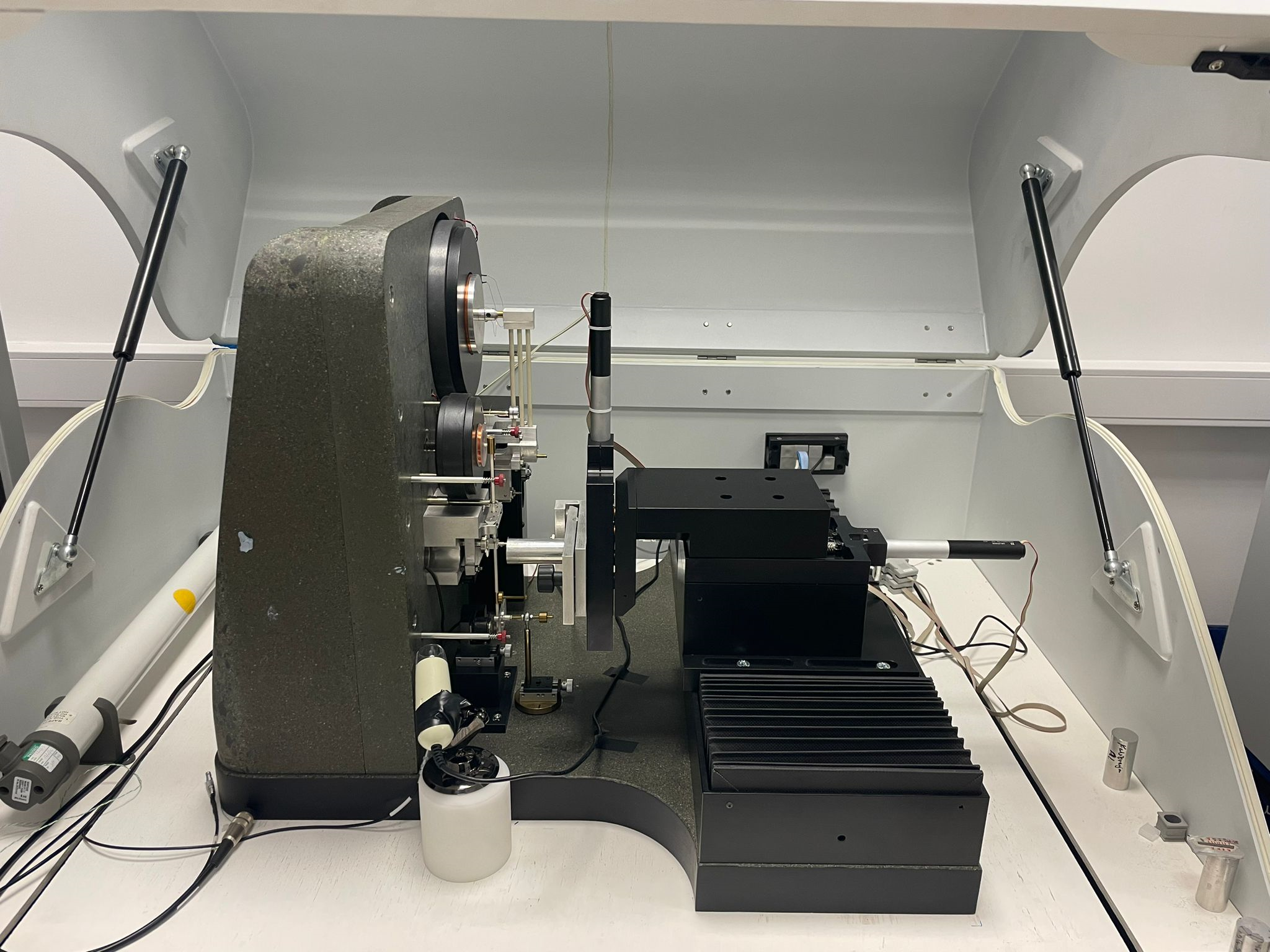

However, with the use of more sophisticated equipment (i.e. videoendoscope), visual inspection can be extended to remote areas (remote examination) that are normally inaccessible to the operator. The use of specialised equipment allows the detection of defects, corrosion changes that cannot be seen with the unaided eye.