NCBJ pioneers research into alloys for next-generation reactors

28-08-2025

Engineers from the National Centre for Nuclear Research (NCBJ) are testing how a special metal alloy – Inconel 617 – behaves under the operating conditions of future nuclear reactors. Inconel 617 is a nickel superalloy that is highly resistant to high temperatures, corrosion and oxidation. This makes it ideal for the construction of components that must operate in extreme conditions, such as heat exchangers in the Generation IV nuclear reactors. However, in order to actually use it in nuclear engineering, it is necessary to know how its properties change under the influence of long-term radiation exposure. That is why scientists from the Materials Research Laboratory and the NOMATEN Centre of Excellence at NCBJ conducted the world's first research on the radiation resistance of Inconel 617 produced using additive manufacturing.

The design of modern Generation IV nuclear reactors poses new challenges for engineers in terms of construction materials. In addition to high resistance to radiation and corrosion, structural components will have to withstand very high temperatures, up to 1000 °C, and mechanical loads for many years. Promising "candidates" for certain applications in the nuclear industry are nickel-based metal alloys, such as Inconel 617.

This alloy has been known in materials engineering since the 1970s and is valued for its high resistance to corrosion at high temperatures and good mechanical properties. This makes it suitable for the construction of reactor components operating at high temperatures, such as turbines, installation connections and heat exchangers. However, the behaviour of this material under prolonged exposure to radiation has not yet been studied in detail. For this reason, scientists from the Materials Research Laboratory and the NOMATEN Centre of Excellence at NCBJ decided to investigate how Inconel 617 alloy behaves under the influence of radiation.

In most cases, components made of Inconel alloys are produced by traditional casting. However, the properties of these materials, such as high hardness, make their further processing complicated. An additional difficulty arises from the fact that many components used in nuclear engineering have complex geometries, which increases the need for machining of the originally cast components. Therefore, alternative manufacturing methods are being explored. One of them is additive manufacturing. In this method, the object is created by applying subsequent layers of material. This allows it to be precisely designed and manufactured, while minimising the material losses characteristic of conventional casting processing.

About the study

In their work, NCBJ scientists used the technique of directed energy deposition (DED). Samples were made by melting metal powder or wire using a laser. The material produced in this way was then implanted with a beam of Fe2+ iron ions to simulate the long-term effects of neutron radiation present in nuclear reactors. This work is the world's first test of the radiation resistance of Inconel 617 alloy produced by the DED method.

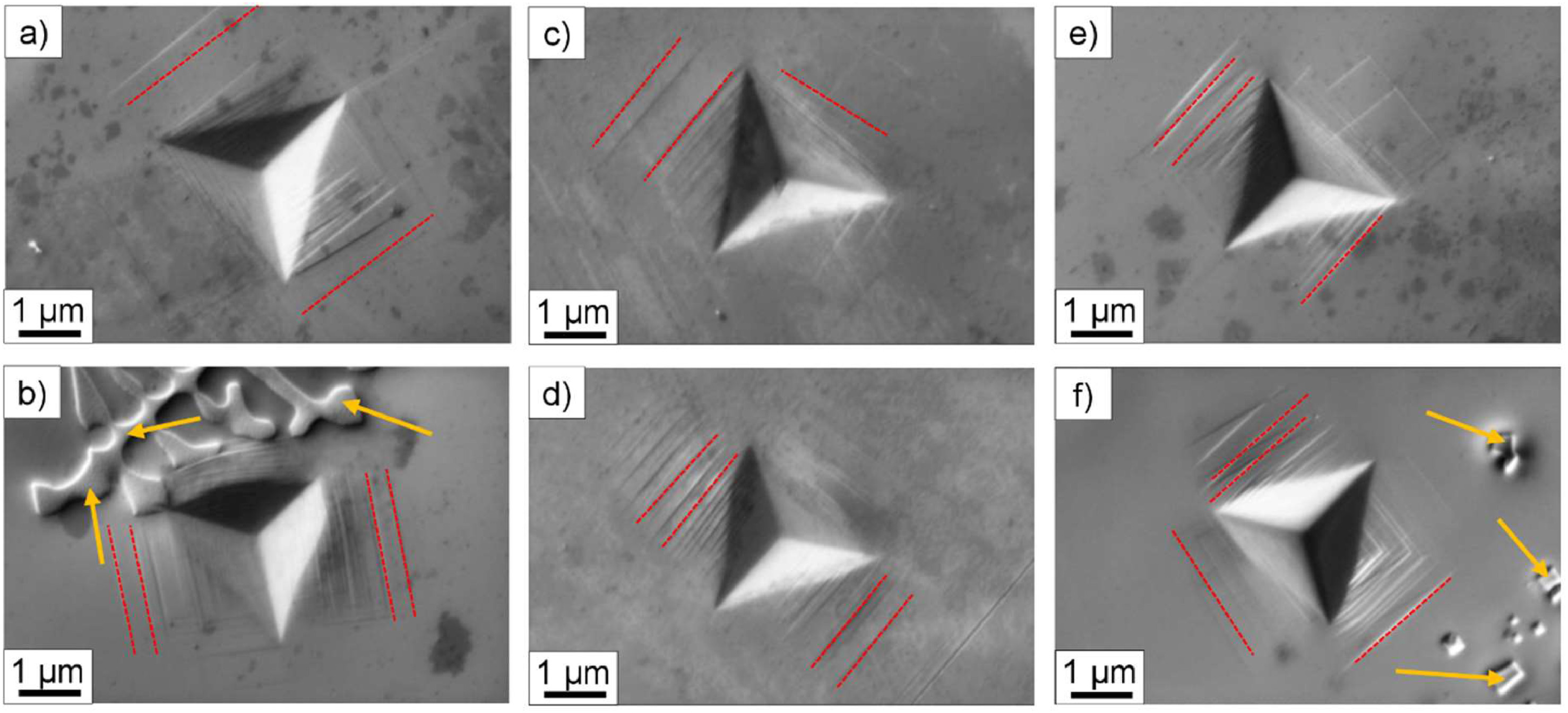

Both the samples exposed to radiation and the initial alloy were subjected to detailed material testing. This allowed the scientists to precisely determine the composition and structure of the alloy using optical emission spectroscopy (OES) and transmission electron microscopy (TEM), among other techniques, as well as changes in properties caused by implantation through microhardness testing and nanoindentation. The latter research technique involves driving an extremely hard indenter into the surface of the material on a nanometre scale to determine its mechanical properties, such as hardness and elastic modulus.

Analyses have shown that, depending on the raw material used (in the form of powder or wire), the microstructure of the alloy obtained differs slightly. - Samples obtained from powder are composed of larger grains and have a higher content of carbides, especially those rich in molybdenum and chromium. This is due to the higher presence of carbon in metal powder compared to wire - says Tomasz Stasiak, PhD from the NCBJ Materials Research Laboratory, the first author of the article. All implanted samples were characterised by increased hardness, comparable to other nickel-based alloys. - The samples exposed to the ion beam also showed a 20-40% increase in hardness compared to the initial samples, which is caused by the formation of defects in the material, especially dislocation loops. Comparing our results with studies of Inconel 617 alloy produced by other methods, it turns out that the additive method results in larger size of defects, but lower density of their formation - adds Tomasz Stasiak.

The results of the research have provided knowledge about how Inconel 617 behaves under the influence of an ion beam and how its properties are affected by manufacturing conditions. This is an important step towards the design and construction of modern, safe Generation IV nuclear reactors.

The full results of the research are available in the publication:T. Stasiak, J. Jasiński, J. Rzempołuch, U. Woy, M. Wilczopolska, K. Mulewska, M. Kowal, K. Ciporska, Ł. Kurpaska, J. Jagielski, Effects of Fe2+ ion-irradiation on additively manufactured Inconel 617 alloy, Journal of Nuclear Materials, Volume 615, 2025, 155978, https://doi.org/10.1016/j.jnucmat.2025.155978.